No more OEM? No Problem!

Custom Ignition Solutions for Your Classic Bike!

My cutting-edge technology simplifies and speeds up your motorcycle tuning experience!

Just connect your phone to your beloved motorcycle, and you’re good to roll!

Imagine the ease of repair work with a programmable ignition that seamlessly adapts to a variety of bikes.

This is a game-changer for any motorcycle enthusiast, particularly when dealing with discontinued or overpriced original parts.

Making tuning a breeze and ensuring your engine performs at its best.

Programmable AC-CDI.

Features

- Wireless Programmable AC-CDI.

- Suitable for ONE or TWO* cylinders

- For [2 strokes engines] and for [4 strokes engines with wasted spark*]

- Easy programming via WiFi connection. (No cable)

- You need a simple web browser on any smartphone or laptop. (No app)

- Compatible Windows, Android, Mac, Linux (No special OS).

- Non volatile configuration.

- ONE or TWO programmable ignition timing curves. *

- Rev from 10 up to 30,000 RPM.

- 0 deg advance from 1 to 500 RPM. (To avoid kickback)

- Adjustable timing in 13 steps from 500 to 20,000RPM.

- Rev limiter.

- Live Display of RPM and Timing via Wifi.

- 1 input for an inductive pickup (VR).

- Support 2 Pickup polarities. (Positive or Negative first). New !

- 1 input for an Hall Effect Sensor, Optical sensors or Points (An external resistor is required) *

- VR conditioner to extract pickup signal in noisy environment.

- 1 output for a CAPACITIVE coil type from 0.3 to 1ohm.

- Stator can be half or full rectified. (For more power and ground isolation)

- 1 input for Kill switch.

- 1 input to select Timing N°1 or N°2 at startup *

- 1 input for Security switch(es) or for a Quick Shifter * New !

- 1 output for 12v Tachometer signal. *

- Power supply voltage DC 6 to 18 volts (For Setup AND to operate).

- Current drain: 30mA – 100mA.

- Protected against reverse supply voltage.

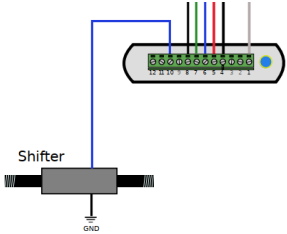

- 300V 8A 12pins connector.

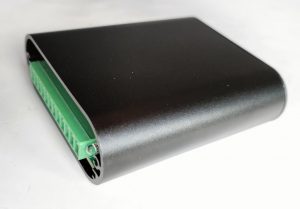

- Dimensions: 75 x 70 x 25mm (2.95 x 2.75 x 1inch) 150gr (5.3oz) Smaller !

- Strong Aluminum box New !

- Potted for Electrical insulation, Protecting components from mechanical shock and vibration, thermal shock or Moisture.

- 6 months Warranty + 1 year Firmware Updates New ! *

- Made in France.

* Options

Programmable ignitions NEED an external pickup to be able to change the advance timing.

The external pickup is the TIMING REFERENCE.

That is why SEM, MVT, PVL, SELLETRA stators with their so-called “internal timing” CANNOT work with this CDI.

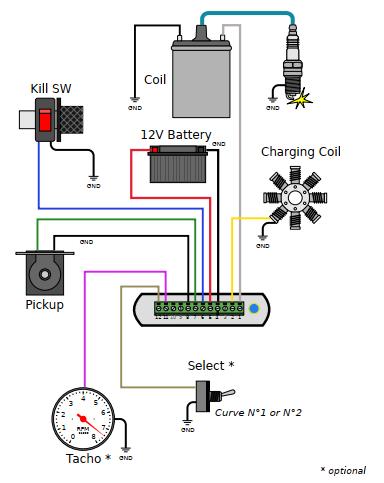

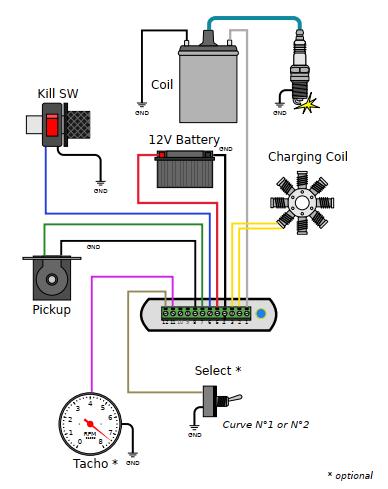

Wiring

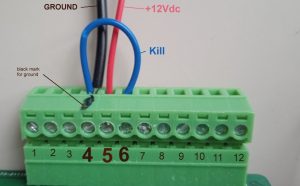

Pin 4 is the black mark

Half-Rectification and Common ground Full-Rectification and Isolated ground. (More power):

12 pins Connector

HowTo wire ACCDIv14 on XT550-600

HowTo wire Sidestand & Neutral switches on XT550/XT600/TT600

Looking for a XT550-XT600 ACCDI (before 1990)? Consider this one !

HowTo setup

To program the ignition, please Print and follow this procedure: Setup Ignition box.pdf

The 12pins connector has a marker trace on pin4 which is Ground.

1) Connect a Black wire from connector pin4 to the black plug of a 12v battery.

2) Wire a bridge between connector pins 4 and 6 (ground and kill input).

3) Connect a Red wire from +12v connector pin5 to the red plug of the battery to power up the ignition.

4) Led blinks 5 + 5 times while a WiFi Access Point named “Transmic_ign” show up on you laptop/smartphone.

(If a password is asked, use “password”)

Cylinders

* Twin-cylinders at 360° crankshaft angle:

The engine works with WASTED spark.

If there is ONE twin coil:

=> This AC-CDI works.

See: CDI compatibility

Pickup

It’s made of a coil of wire wrapped around a magnet.

When a ferrous part passes by the magnet, the magnetic field is modified and a voltage pulse is created in the coil generating a sine wave.

ACCDIv14 has:

– 1 input for inductive pickup (VR/pickup coil) with 1 signal per crank revolution. (Pickup must puts out 3 to 100Vac)

– 1 optional input for Digital sensor (Hall Effect Sensor, Optical sensors even Contact breaker).

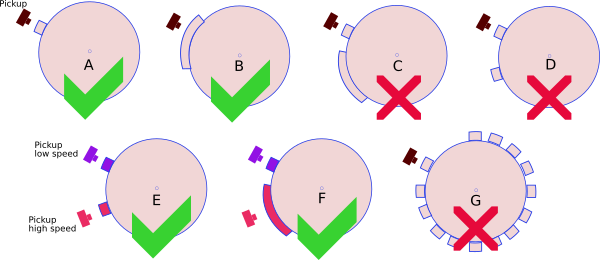

– This CDI works with ONE pulse per rev (1 reluctor only like “A” or “B” below)

– This CDI DOES NOT work with multi-pulse pickup (ie 2 reluctors on flywheel: “C” or “D”).

– This CDI DOES NOT work with a missing tooth flywheel. (“G”)

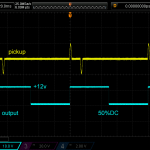

Pickup Polarity

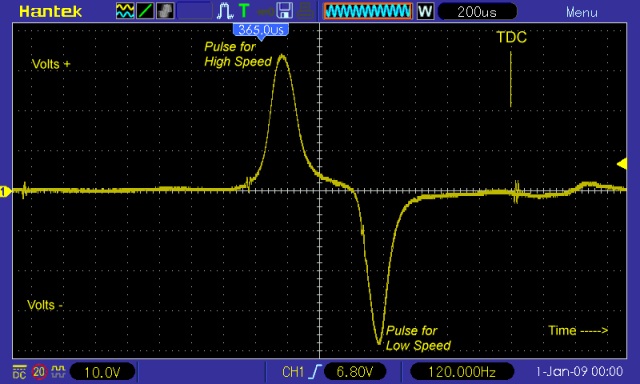

When the bar/magnet on the stator passes in front of the pickup, the pickup generates two pulses of OPPOSITE polarity.

A pickup has 2 wires.

– If you ground wire number 1, wire number 2 will put out a Positive pulse first when the rising edge comes, then a Negative pulse when the falling edge leaves. I call it PN.

– If you ground wire number 2, wire number 1 will put out a Negative pulse first, then a Positive pulse. I call it NP.

This ignition box works best with Positive first pickup. (VR-PN)

If the polarity is Negative then Positive(NP) then the leads are backward, if possible, just swap the wires to change the pickup polarity !

Watchout! If the pickup is internally grounded and output ONLY one wire, you won’t be able to change the polarity, the pickup output is either PN or NP. You can still use this ignition.

Check the polarity of the pickup (Negative going then Positive/(NP) or the opposite PN: Positive going then Negative) with a Needle galvanometer (in milliAmp position) while kicking.

Pickup Position

“Pickup Position” is the number of degrees between the very first pickup pulse and TDC.

This ACCDI can use Pickup Position from 1 to 180° BTDC

To be able to provide the largest advance timing (Example 36° @ 4500rpm) the pickup MUST send a trigger signal BEFORE the piston reaches 36° before top dead center (BTDC).

The “Pickup Position” on the Yam XT600 is 50°. Many Yamahas have a “Pickup Position” of 72 degrees.

This “Pickup Position” depends on:

– Where the pickup is mechanically located with respect to TDC?

– Where is the flywheel’s bar located?

– How long is the flywheel’s bar?

“Pickup Position” AKA “Max Advance” = “Base Advance” + “Flywheel’s bar Length”

“Base Advance” value sometime appears in the User Manual.

Length of the flywheel’s bar can be measured this way.

You may measure the “Pickup Position” using a protractor.

or with a caliper and some math.

Pickup Voltage

The higher the RPM, the more voltage it must produce

Formula : Minimum Pickup voltage = RPM/1000 + 3

Example : At 6000rpm the VR pickup must put out : 6000/1000 = 6 + 3 = 9Vpp (Volts peak to peak)

Hall Effect Sensor, Points/Contact breaker

Optional

– Points, reluctors, Hall sensors, optical sensors can also be used as long as they give only 1 pulse per revolution.

– When a magnet passes in front of the sensor, the output voltage goes low.

The ignition box will detect the LOW to HIGH transition, meaning the trigger moment will be when the magnet LEAVES the hall sensor.

– Work with NPN Models : NJK-5002C, Hamlin 55100, Allegro A1101-A1104, Allegro old 3141-3144, Honeywell 1GT101DC, SS495, SS49E etc…

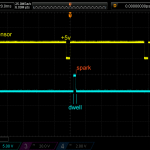

Live Display of RPM vs Timing via Wifi

For diagnostic or tuning purpose, it’s possible to live view RPM and Timing in degrees BTDC on a remote PC connected through Wifi: Video Because of the impact on CDI performance, please disable this function when you are done with it!

Ignition timing

Windows software: Interactive_Graph.exe

(Extract this software to where it has read/write permission, i.e. in your Document folder)

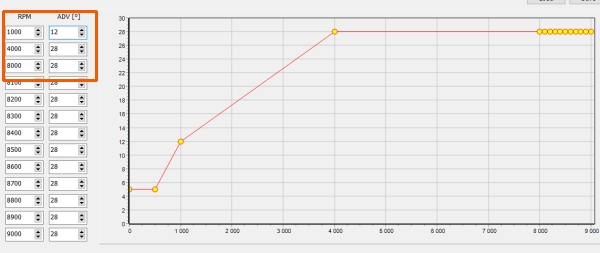

Tip: No need to use all 13 points if the curve is straightforward.

Just use the first 2 or 3 timing pairs ! The ignition box will process that faster.

– Example of Settings for Yamaha XT600 – 1986

Rev Limiter

The last RPM value that has been entered is the “rev limit” that stop all sparks.

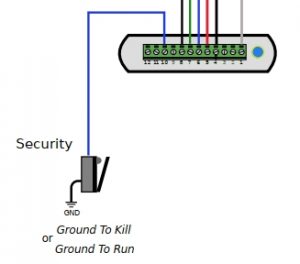

Security / Shifter

The Switch can be one of those 2 type: Gnd2Run or Gnd2Kill

It’s possible to connect more switches of the same type in parallel.

or a Shifter adjustable from 10 to 200ms.

Tachometer

Diagnose with LED.

The led blinks in time when a pickup signal is detected.

– If the box is started in RUN Mode and you have selected Curve N°2: The Led flashes 2 times then stays Off.

The led blinks in time when a pickup signal is detected.

– When the Maximum RPM is reached, the led turns off. If minimum RPM is reached, led turns off.

– When the box starts in SETUP Mode : Led blinks 5 times fast, 2 seconds off, blinks 5 times fast again, then flashes once every 5 seconds. (See video) The led flashes briefly when data reaches the box through WIFI.

COIL

CDI ignitions need a CAPACITIVE coil type (AKA Transformer type) for CDI (Not a INDUCTIVE coil for TCI)

Ignition coils are different from TCI to CDI systems.

A CDI ignition can work with a TCI coil but the spark energy will be halved ! Why CDI coils don’t work with TCI ignitions?

– CDI coils have low inductance (L=0.1 to 0.7mH) and primary resistance of around 0.3 to 0.8ohm

– TCI coils have higher inductance (L=4 to 15mH) and primary resistance of around 1 to 5ohm

CDI coils: IMFsoft, Ignitech, FireCore, FuelTech, PW, M&W, Suzuki coil, Kawazaki coil, PVL double coil, Honda double coil,

Important criteria for choosing a coil:

Primary resistance: 0.2 to 0.6 Ω. The lower the resistance, the better for a CDI (less Joule losses).

Primary inductance: 0.2 to 1 mH. Must be low for fast charging/discharging.

Maximum charging voltage: ≥ 400 V. Must withstand the capacitor’s discharge voltage.

Delivered energy: 30 to 80 mJ depending on the system. Direct influence on spark power.

Current rise time: < 1 µs. Faster = better combustion at high RPM.

VERSIONS

- Version v14r0c0:

- Evolution of V12.

- [soft] New menu. User can select strokes and cylinders.

- [soft] 2 timing curves available.

- [hard] 1 switch to select timing curve.

- Version v14r1c0:

- [soft] Bug fixes.

- [soft] Change GUI.

- Version v14r2c0:

- [soft] Bug fixes.

- Version v14r3c0:

- [soft] Bug fixes.

- [soft] Increase advance at idle.

- Version v14r4c0:

- [soft] Bug fixes.

- [soft] Change GUI.

- [soft] Add Shifter input.

- [soft] Reduce memory usage.

- Version v14r5c0:

- [soft] Reduce code size.

- [Soft] Faster code +18%

- [soft] Start RPM is now 150.

- [soft] Improve GUI.

- [soft] Add html page to check eeprom content.

PHOTOS.

Transmic CDI vs Honda CDI ? Dyno speak volume:

Honda NSR125 with Malossi 180cc, Tyga exhaust, Italkit reeds tuned by “Cuco Racing Team – Spain”

Yamaha XT600 49L 84′ with CDI v11:

VIDEOS

Gilera Saturno 500 1988 v14:

Yamaha TT600S without battery v12:

Yamaha TT600S with battery v12:

Yamaha XT200 with CDI v10:

Yamaha XT600 with CDI v11:

Yamaha XT125 with CDI v11:

Yamaha TTR600 with CDI v11:

Sanglas converted from points to CDI v11:

Honda MBX 125 onboard with programmable CDI v10:

Various parameters must be memorized beforehand

I recommend to roughly determine the position of the sensor with a graduated disc

The stator must be labeled for a pre-adjustment with 10,20,30° marks

First try with a car battery

The positive pulse from the pickup must come first, otherwise swap the cables, otherwise the timing will be clearly wrong

So not this way !

The engine runs under 6v under its own power supply

5 degrees offset

Offset corrected

Will it go with the Vape too?

Safe settings: pickup position:70/pickup type:0/adv 0-500:0/5@1000/5@2000/10@3000/20@4000/30@6000

great job congratulations! I wanted to ask you, in your opinion is it possible that it works on a vespa 50 (pk 50 s) with electronic ignition? In this case I’m talking about the original Ducati 4-pole ignition with pick-up on the stator. In case I can send you some photos or you can find them on the internet! Thanks and Merry Christmas!

Thanks!

Is it this one ?

If it has one external pickup, only one bar on the flywheel and a +12v battery: Yes it works.

You just have to be sure that the pickup puts out a positive pulse first otherwise you’ll have to invert the 2 wires that go the pkp.

(Read Pickup polarity section in this page)

Regards

Hello! I only saw the message now! Then the stator (4 poles) has the internal pickup and the external HV coil. is the model without battery!

https://www.vesparesources.com/uploads/monthly_2017_10/59e8913d20b4a_Schermata2017-10-19alle13_48_50.png.cb30d83fcfca90e9a2d12b8bc12423e4.png

Thanks for the Answer! I want the V11 so bad but from the text I took it that it sadly won’t work with 2 pick-ups, right?

After reading the text more thoroughly, I think that two pickups should work, but I’m not sure where I can connect the second one, just to the same port as the first? (That can’t be right, can it? )

Or do I not need two pickups at all with the programmable ignition curve and one is enough? (sorry for the spam)

You took it right. ACCDIv11 DID NOT used 2 pickups.

In fact it didn’t need the LOW pickup that sends a pulse at 12°btdc

The cdi uses the HIGH rpm pickup at 36° to make 12° from it.

I’m currently testing a new version of ACCDIv11r5c1 with added features (See https://transmic.fr/2021/08/14/ac-cdi-v11/#versions )

This version now uses the two pickups on XT550-600 but I haven’t got the time to write the documentation…

Thank you so much!

I think I’m slowly getting there.

now I ask myself only the question with the wiring. I have the circuit diagram from am motorcycle, sind from the pickups come 3 cables: 12°, 36° and the pickup ground. Is said ground important or is it simply ignored?

and what exactly is the HV cable in your wiring scheme? a brown and a red cable come out of my alternator, where do i connect them? 🙂

Oh i see now your updatet wiring, thanks! going to purchase 😀

I have purchased this excellent product for older 4-stroke motorcycles, programmable curve between 0 degrees and 38 degrees. Thank you for your help and knowledge on these products.

Ciao Thierry, do you have any experience using your CDI on a points Piaggio Ciao / Bravo ?

Hi,

No. But there is not improvement in performance to expect on a 50cc…

ahahah…you are right but i m interested more in reliability than in performance !

Hello,

Looking for a cdi for Artic Cat spirit 500 2cyl 2 stroke. Have your accdi 2.7+ and have had the motor running but not well. nipponddenso 070000-0680 is factory unit cdi. Can you help out..

I think that the most reliable assembly is a TCI with a Hall sensor so there is no use of the alternator neither the pickup coil, but it needs a battery and it’s a big mod !

Hello,

You mean the Artic Cat snowmobile with the “Spirit” engine from Suzuki?

It seems to be a 360° parallel twin (both pistons up and down simultanously)

Beside it runs with the ACCDIv27+ so I bet there is only ONE pickup and a twin ignition coil to fire both cyl. at the same time.

Sure the ACCDIv27 is a crude ignition created as an affordable solution.

If you want to fine tune the advance timing, the ACCDIv11 is better (or a TCIv11 but the ignition coil MUST be replaced)

To set the v11 you MUST know the pickup position BTDC, don’t ask me 🙂

I described same ways to do it on both web pages.

Th

bonjour Thierry,

je suis motivé pour prendre la v11 pour ma xt 600 3TBK.

Petite question suite à la lecture de tes commentaires et quelques recherches :

la version ACCDIv11r5c1 permettrait d’utiliser les 2 capteurs (12° et 36°) si je vous comprends bien.

par contre il y’a une mofif Hardware dans la ACCDIv11r5c1 pour une deuxième entre analogique pour le capteur 12° donc.

La version actuellement en vente serait compatible ou dois-je attendre encore ?

Encore merci pour ton travail

Bonjour et merci pour votre commande.

La version a ce jour est ACCDIv11r6c1 donc elle integre de r5c1 une entrée pour le pickup low a 12° dans le cas des XT600.

merci pour votre réponse.

Colis réceptionné ce jour, merci !!

Déjà connecté dessus j’ai un petit doute quand à la valeur du PICKUP

(oui mon anglais est …. fatigué.. et malgré google traduction je ne suis pas sur de comprendre)

en fait ces deux phrases me mette le doute :

“The “Pickup Position” on the Yam XT600 is 50°”

“The cdi uses the HIGH rpm pickup at 36°”

pourquoi 50° , on a un capteur 12° et un autre 36°

pouvez-vous svp me confirmer pour un 600XT:

PICKUP TYPE : 0 (vr analog)

PICKUP POSITION : 36 (BTDC)

aussi dans la documentation il n’y pas d’indication concernant SHAFT: Crankshaft ou CamShaft

je suppose que c’est pour ceux qui on le capteur sur le haut moteur ?

je laisse donc Crankshaft pour mon utilisation.

Encore merci,

hâte de tester sur la moto !!

Le pickup de la Yamaha XT600 est physiquement placé à 50°.

Le CDI attend un peu puis envoi l’étincelle à 36° BTDC.

Les pickups sont TOUJOURS positionnés a une valeur SUPÉRIEURE à la valeur d’avance maximale.

(pour obtenir 36° d’avance max, les ingénieurs Yam auraient pu placer mécaniquement le capteur a 37, 50, 70, 93° btdc etc, le CDI se débrouille mais il faut le lui dire.)

PICKUP TYPE : 0 (vr analog)

PICKUP POSITION : 50 (BTDC)

>je suppose que c’est pour ceux qui on le capteur sur le haut moteur ?

>je laisse donc Crankshaft pour mon utilisation.

Evidemment.

Merci pour votre réponse plus que complète !

Demain ça démarre du coup, j’ai hâte !

Bonjour ,

Je viens donner nouvelles,

j’ai enfin eu le temps de monter le CDI sur ma moto.

Malheureusement après de bonnes heures de recherche je sèche -> pas d’étincelles.

1) j’ai mesuré à l’oscilloscope je pense l’essentiel des composants (je peux faire des captures si besoin ?)

– vérif de la tension HT du stator : OK (sinus de -150v à +150v environ)

– vérif du capteur PICKUP : OK (premier pic positif d’environ 7v suivi du négatif à -7v)

2) j’ai enlever le faisceau elec de la moto et fait un faisceau sur mesure pour uniquement cabler le CDI tel que sur le schema “full rectification” (avec un inter pour le “kill switch” pour accéder au paramétrage facilement)

– je n’ai pas essayé en Half-rectification par contre.. mais je ne verrais pas pourquoi ce serait mieux

3) batterie neuve chargé ou alimentation de labo pour le 12v (avec test de masse différentes pour être sur , cadre, moteur, sur le régul, etc..)

4) bougie neuve, bobine neuve, antiparasite neuf (même si à l’ohmètre tout était bon mais j’avais ça en stock donc autant essayer)

-> les symptôme sont :

– sur la broche 1 (sortie CDI pour bobine) il n’y a rien : mesuré à l’oscillo. (bobine branchée ou non branchée)

– la led du boitier clignote si je fais tourner le démarreur ou un coup de kick (je suppose donc qu’il capte bien le PICKUP)

– j’ai mis une courbe d’avance simple à 3 points (500-8 ; 1000-10 ; 6000-30 ) , si je fais “READ” c’est bien écrit comme dans la doc.

Voilà, je vous avoue que je sèche . ça fait beaucoup à lire mais je tenais à essayer d’être le plus précis possible. Avez-vous une idée ou une piste ? je peux bien évidemment mesurer ou fournir d’autre informations si nécessaires

En vous remerciant par avance,

Robin

>la led du boitier clignote si je fais tourner le démarreur

Donc le CDI voit bien le pickup

>sur la broche 1 (sortie CDI pour bobine) il n’y a rien

C’est qu’il manque la Haute Tension

Essayez en Half rectification. J’ai vu des cas ou ca ne marchait pas en full. Surement a cause de masse non communes…

Th

Si besoin joignez moi directement par PM (mon adresse est en haut a dr. “Contact Me”)

Après des heures de recherches le résultat est tombé : STATOR HS .

Encore merci pour les nombreux conseils et pour l’aide apporté.

A bientôt j’espère et bonne continuation !

do you plan on adding TPS support and therefore ignition mapping with rpm and throttle position to those devices?

No. One day perhaps but surely not yet.

To make a universal TPS input, you must deal with 2, 3 or 5 wires sensors. Sensors that go forward or backward, sensors that provide voltage, different min and max voltage or provide ohm resistance value… etc etc

And of course a real time 3D mapping. If you need more look at Megasquirt.

Compare Honda CDI WITH TPS vs Transmic CDI WITHOUT TPS:

https://transmic.fr/wp-content/uploads/2023/02/ACCDIv11_Dyno_Honda_NSR125.jpg

Good morning,

I wanted to check the “pickup position” angle (50 degrees on my yamaha XT600) with the stromboscopic lamp.

I set a fixed curve from 500 rpm to 6000 rpm: fixed advance 12 degrees. (and I increased the idle to 2500rpm)

I can’t get a fix point on the flywheel. it moves a lot so very difficult to adjust the value of “picikup position”.

I see the “TDC” mark through the hole with the strombo lamp so I already have almost 12 degrees not good

So my question are: What I’m doing wrong or what’s the precision of this CDI ?

(I can’t film, problem with frame rate and oil vapor projection, but I’m motivated for other tests)

Thanks in advance

Hello Thierry. I got an CR500 with an Aftermarket ignition from panthera. It has inside 90W light coils and one ignition coil. I will have a batterie installed. I got one Accdi and one dcccdi from you. Can i Connect the ignition coil too, or leave it alone? Second bike is Peugeot 103 with the original CDI ignition, how to Connect this to your ecu. I didn’t found a picture, where i can connect the ignition coil for power your cdi. Regards Frederick Krosse

[Open a NEW thread, don’t REPLY to a 3 years old comment!]

Hi, The ignition coil is the one connected to the sparkplug. I suppose you mean the Charging coil.

Of course ACCDI MUST be connected to the charging coil (high voltage output from stator)

DCCDI don’t need charging coil. You have version v12. On this one you can also connect a charging coil between pin2 and pin4/ground.

This way you have both charge but I think it’s useless and I never tested it.

First Peugeot 103 in the 70′ 80′ were with Magneto. Doesn’t work with my ACCDI.

If yours is ACCDI with external pickup, (like this one https://www.youtube.com/watch?v=XlIyjoU_ywg) you can connect it to ACCDI.

Which wires? I f… don’t know! Send me a wiring diagram and I will tell you.

Perhaps this YT video would help: https://www.youtube.com/watch?v=yUO2bCfuNSQ

Best

Salut Thierry!

First of all thnaks a lot for all the information you provided and respect for the excellent work!

I’ve been following your endeavours for some years now and am pretty impressed about the development your ignitions have gone through.

I’m just about to order an AC-CDIv14 to replace the stock unit on a ’87 XT600 2kf and tried to read and understand as much of your documentation as possible including the wiring schematics and the circuit for the combined neutra and side stand switch.

Upon reading the ‘Setup_IgnitionBox_ACv14r3c4’-document I have one question I would like toi clarify prior to ordering, though:

Does

“/!\ For XT550-XT600 only: Kill the engine with the Kill switch BEFORE shutting down the +12v.

(As it’s a soft ware kill, the processor must be powered on to be able to kill the engine!)” on page 39

refer to standard running mode and actually mean that you can’t shut off the engine by the ignition key any more?

If so,

– what would happen if somebody turned off the ignition key with the motor running

(fry CDI or voltage regulator/generator)

– is there a workaround (like e.g. for neutral & side stand switch combination) to allow for

shutting off the engine with the ingition key like on the stock CDI?

Thanks a lot for any help and information you can provide on this already now!

Best regards and keep up the brilliant work!

L.

Halo Lutz,

Thanks for your kind words.

In one word, if you just want a replacement of the XT600 unit, then go for: https://transmic.fr/product/ac-cdi-v12-xt550-600/ it works the same EXCEPT the securities switches.

If you want the same security behavior as original, you’ll have to add an extra circuit: https://transmic.fr/wp-content/uploads/2024/03/Securite_bequille_XT-TT.pdf

– AC-CDIv14 is only needed if you want to TUNE the advance timing.

>actually mean that you can’t shut off the engine by the ignition key any more?

Right, you have to kill the engine first.

>what would happen if somebody turned off the ignition key

Nothing, the engine continues running 🙂

>is there a workaround to allow for shutting off the engine with the ingition key?

The only workaround is to NOT use the 12° pickup. Meaning risk of kickbacks…

Th

Salut Thierry,

thanks a lot for the soon reply and all the information!

Although I like the ability to tweak the parameters and advance curve(s) and hence the resulting versatility of the v14 I will have a closer look at the v12 before I do some shopping…

I’ll get back to you soon…

Best regards and thanks again!

L.

Hello! I bought a Chinese Daytona ignition for my motorcycle

and I want to program pre-ignition.

the motherboard has a factory charging coil with voltage regulator and an ignition coil.

which type do you recommend using?

because you have to use an accumulator for all of them, right?

AC-CDI ignition coil or DC-CDI battery, because I have a charging coil, right?

the link is about collection

https://www.aliexpress.com/item/1005004891079017.html

Thank you in advance for your time!

I don’t really understand your question.

By « pre-ignition » you mean « advance timing » I suppose.

>which type do you recommend using?

Type of what ?

The ignition you bought is a AC-CDI. It should be replaced by another AC-CDI

My AC-CDIv14 use a 12v battery and should work but the problem is that the magnet + pickup setting of the Chinese kit DO NOT allow you to increase the advance timing!

There are too close to each other.

Even with a programmable ACCDI it will be impossible to have 30° of advance with THIS flywheel and pickup. You would have to MOVE the pickup or/and the flywheel.

Hi! yes, I bought an ac-cdi ignition!

I can place the pickup anywhere because a unique motherboard will be made for it

won’t that be a good solution either?

yes. it’s ok then.

For the position of the pickup, read “Appendix1” from Setup.pdf

Thank you! I ordered the device