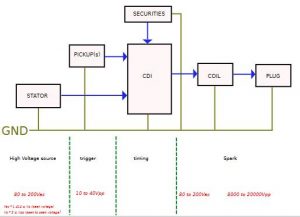

This is a simplified view of how a CDI works.:

We directly see that a “No spark” issue could come from any of the 6 boxes.

That also shows how critical are good ground/frame connections everywhere, not just the gnd attached to the CDI !

“No spark” could come from a rusty plug inside the loom, a broken wire or, from right to left:

– Faulty sparkplug, cap or plug wire.

– Faulty coil. (The coil multiplies the CDI output voltage by 100x)

– Faulty CDI.

– Faulty Securities.

Kill, Neutral, Clutch, Sidestand switches that stop the CDI when they are not supposed to.

Active security = no spark

– Faulty pickup.

The pickup triggers the CDI when it’s the right moment to spark. (Some bike have 2 pickups)

No trigger pulse = no spark

– Faulty Stator.

The stator include one High Voltage coil that load the internal capacitor of the CDI.

No HV = no load = no spark

From left to right:

– To test the stator, remove the sparkplug, disconnect the stator from the CDI, crank the engine.

Measure on stator side with an oscilloscope or a multimeter with a DVA adapter in DC position.

You should read around 80 to 120Vdc (peak voltage)

Replace the stator by 2 transformers or a DC converter.

– To test the pickup, remove the sparkplug, disconnect the pickup from the CDI, crank the engine.

Measure on pickup side with an oscilloscope or a multimeter with a DVA adapter in DC position.

You should read around 5 to 10Vdc (peak voltage)

– To test the Securities, disconnect each security switch one by one from the CDI.

With a multimeter in continuity mode, check the continuity between each wire (switch side) and the ground (for Kill, Neutral, Clutch, Sidestand)

Warning!

Some CDI want the security to be grounded in order to run: Bypass the safety sw to ground to test.

Some CDI want the security NOT to be grounded in order to run: Disconnect the safety sw to test.

– To test the CDI, there is no easy way.

Measure the resistance against the user manual

Replace it by a known-good cdi

Test the cdi on a known-good bike.

Disconnect the coil from the CDI, measure on CDI output with an oscilloscope or a multimeter with a DVA adapter in DC position. Crank the engine, you should read the same voltage as on Stator output: Around 80 to 120Vdc (peak voltage)

Replace it with a very crude CDI like mine.

– To test the ignition Coil, measure the resistance against the user manual

Replace it by a known-good coil.

Test the coil on a known-good bike.

Remove the coil from the bike and test it with a diode and a capacitor.

I’d like to build the AC cdi fory gn400. How would I determine the scriptures output to set the solder pad switches? Is it trial and error or is it known?

I don’t understand your question. “the AC cdi” the refers to what? sriptures output ??

There are some bit of info on GN400 here and there.