Programmable DC-CDI

DC-CDI v12 is End Of Live and has been replaced by DC-CDI v14

This technology will make your motorcycle tuning much simpler and faster.

Just connect your phone to your motorcycle and you’re ready to go!

A programmable ignition is extremely valuable in repair work as it fits a wide range of bikes.

It’s especially useful if the original part has been discontinued or is overpriced.

And of course it’s a must-have if you are wishing to tune the engine.

Features

- Programmable DC-CDI

- Suitable for ONE or TWO* cylinders

- For [2 strokes engines] and for [4 strokes engines with wasted spark*]

* On 4stk engines with a pickup on the crankshaft, one spark occurs during the compression stroke and another during the exhaust stroke.

- Easy programming via WiFi connection.

- You need a simple web browser on any smartphone or laptop. (No app)

- ONE or TWO programmable ignition timing curves. *

- Rev from 10 to 20,000 RPM.

- 0 deg advance from 1 to 500 RPM. (To avoid kickback)

- Adjustable timing in 13 steps from 500 to 20,000RPM.

- Rev limiter.

- Live Display of RPM and Timing via Wifi.

- 1 input for an inductive pickup (VR). Pickup polarity MUST be Positive first.

- 1 input for an Hall Effect Sensor, Optical sensors or Points (An external resistor is required) *

- VR conditioner to extract pickup signal in noisy environment.

- 1 output for a Capacitive coil type.

- 1 input for Kill switch.

- 1 input to select Timing N°1 or N°2 at startup *

- 1 output for 12v Tachometer signal. *

- 2 settings of High Voltage 150 or 300Volts.

- Power supply voltage DC 6 to 14 volts (For Setup AND to operate).

- Current drain: 100mA – 2A.

- Protected against reverse supply voltage.

- 300V 8A 12pins connector.

- 80MHz MicroController control unit.

- Non volatile configuration.

- Dimensions: 100 x 60 x 25mm (3.9 x 2.4 x 1inch)

- Plastic box potted for Electrical insulation, Protecting components from mechanical shock and vibration, thermal shock or Moisture.

- Made in France.

* Options

Cylinders

* Twin-cylinders at 360° crankshaft angle:

The engine works with WASTED spark.

If there is ONE twin coil:

=> This AC-CDI works.

See: CDI compatibility

Pickup

It’s made of a coil of wire wrapped around a magnet.

When a ferrous part passes by the magnet, the magnetic field is modified and a voltage pulse is created in the coil generating a sine wave.

DCCDIv12 has:

– 1 input for inductive pickup (VR/pickup coil) with 1 signal per crank revolution. (Pickup must puts out 3 to 100Vac)

– 1 input for Digital sensor (Hall Effect Sensor, Optical sensors even breakerpoints).

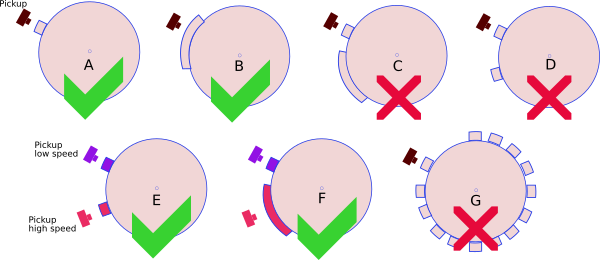

– This CDI works with ONE pulse per rev (1 reluctor only like “A” or “B” below)

– This CDI DOES NOT work with multi-pulse pickup (ie 2 reluctors on flywheel: “C” or “D”).

– This CDI DOES NOT work with a missing tooth flywheel. (“G”)

Pickup Polarity

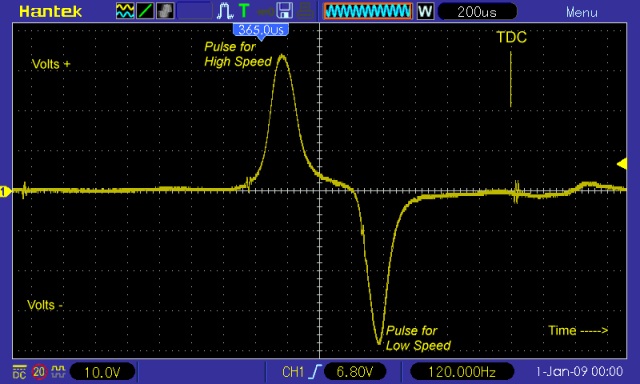

When the bar/magnet on the stator passes in front of the pickup, the pickup generates two pulses of OPPOSITE polarity.

A pickup has 2 wires. If you ground wire number 1, wire number 2 will put out a Positive pulse first when the rising edge comes, then a Negative pulse when the falling edge leaves. I call it PN.

If you ground wire number 2, wire number 1 will put out a Negative pulse first, then a Positive pulse. I call it NP.

Pickup Polarity MUST be Positive then Negative. to work with this CDI.

Check the polarity of the pickup (Negative going then Positive/(I call it NP) or the opposite PN: Positive going then Negative) with a Needle galvanometer (in milliAmp position) while kicking.

If the polarity is Negative then Positive(NP) then the leads are backward, just swap the wires to change the pickup polarity !

Watchout! If the pickup is internaly grounded and output ONLY one wire, you won’t be able to change the polarity.

So if the polarity is NP (Negative first) then you CANNOT use this ignition!

Pickup Position

“Pickup Position” is the number of degrees between the very first pulse from the pickup and TDC

To be able to provide the largest advance timing (Example 36° @ 4500rpm) the pickup MUST send a trigger signal BEFORE the piston reaches 36° before top dead center (BTDC).

The “Pickup Position” on the Yam XT600 is 50°. Many Yamahas have a “Pickup Position” of 72 degrees.

This “Pickup Position” is dependent on:

– Where the pickup is mechanically located with respect to TDC?

– Where is the flywheel’s bar located?

– How long is the flywheel’s bar?

“Pickup Position” AKA “Max Advance” = “Base Advance” + “Flywheel’s bar Length”

“Base Advance” value sometime appears is User Manuel.

Length of the flywheel’s bar can be measured this way.

You may measure the “Pickup Position” using a protractor.

or with a caliper and some math.

Hall Effect Sensor, Points

Optional

– Points, reluctors, Hall sensors, optical sensors can also be used as long as they give only 1 pulse per revolution. They may need an additional pullup resistor.

– 3 wires digital Hall effect sensors need an external pull-up resistor. The default voltage output is equal to Vcc (+5v to 24v). When a magnet passes in front of the sensor, the output voltage goes low and the ignition will detect the RISING edge meaning the trigger moment will be when the magnet LEAVE the sensor.

Models : Hamlin 55100, Allegro A1101-A1104, Allegro old 3141-3144, Honeywell 1GT101DC, SS495, SS49E etc…

Pullup resistor: 370ohm (270 to 1200ohm)

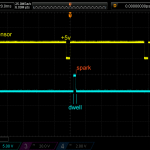

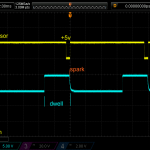

Live Display of RPM vs Timing via Wifi

For diagnostic or tuning purpose, it’s possible to live view RPM and Timing in degrees BTDC on a remote PC connected through Wifi: Video

Because of the impact on CDI performance, please disable this function when you are done with it!

Ignition timing

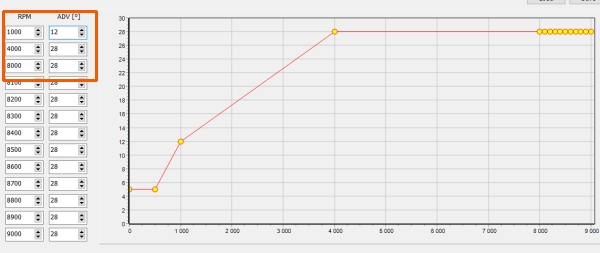

Windows software: Interactive_Graph.exe

Tip: No need to use all 13 points if the curve is straightforward.

Just use the first 2 or 3 timing pairs ! The ignition box will process that faster.

Rev Limiter

The last RPM value that has been entered is the “rev limit” that stop all sparks.

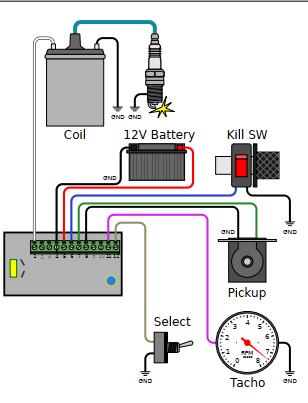

Wiring

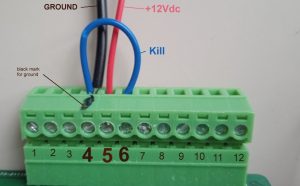

Pin 4 is the black mark

HowTo setup

To program the ignition, please Print and follow this procedure: Setup Ignition box.pdf

The 12pins connector has a marker trace on pin4 which is Ground.

1) Connect a Black wire from pin4 to black plug of a 12v battery.

2) Wire a bridge between ground-pin4 and kill-pin6.

3) Connect a Red wire to +12v pin5 only.

Don’t mix them up !

4) Connect the Red wire to the red plug of the battery.

5) Led blinks 3times while a WiFi Access Point named “Transmic_ign” show up on you laptop/smartphone. (If a password is asked, use “password”)

Diagnose with LED.

As soon as a pickup signal is detected, led blinks in rhythm.

If the Maximum RPM is reached, the led turns off. If minimum RPM is reached, led turns off.

– If the box starts in SETUP Mode : Led blinks 5 times before flashing once every 5 seconds.

When data arrives via WIFI, led briefly flashes.

PHOTOS.

Legal Eagle XL airplane with half VW engine. Twin cylinder, 4 strokes. 0.5-ohm Buick twin-post coil, MSD wires, Champion plugs, Hall sensor + DCCDIv12.

VIDEOS

VERSIONS

- Version v11r8c0:

- POC

- Version v12r1c0:

- Evolution of V11.

- [soft] New menu. User can select strokes and cylinders.

- [soft] 2 timing curves available.

- [hard] 1 switch to select timing curve.

Hi, Thierry.

Which type of dc-dc converter will be used?

I am trying to build ignition based on Arduino and little bit stuck with dc-dc converter.

I want to use converter without transformer. Is it possible ?

Hi

It’s a Royer oscillator. https://en.wikipedia.org/wiki/Royer_oscillator

Unfortunately you cannot reach 200v with strong power without transformer!

At 10000rpm you need a very fast load of the capacitor.

Thank you.

So, will the HV module be used, something like in dc-cdi version 7?

you can be inspired by http://cx500ww.de/schrauberecke/arduino-cdi/index.php

With this new DC-CDI all programming is done through smartphone and no Pickit3 is required? Sounds great! Waiting to hear pricing & availability.

Totally!

The pricing will be based on ACCDIv11 + price of a DC-DC converter.

Furthermore, the FW will be updated to v12 with a second curve available optionally.

Will come out on mid-April.

Very interested in this is it possible to purchase a complete system for Suzuki intruder vs1400 (1987) and also interested in a complete set up for most inline 4 cylinder bikes?

IMO for a big bore like that TCI is better. DCCDI are for fast small engines.

Suzuki intruder vs1400 is a 45° twin so both cylinders never fire at the same time.

You should need 2 units (2 TCI) or 1 unit specially developed for this bike with 2 outputs.

Would this work on a Kawasaki zx7r?

Features

Suitable for ONE or TWO* cylinders

What do you recommend as the optimum primary coil resistance for this ignition? Engine rpm 2000-4000.

Any capacitive coils for CDI with primary resistance of around 0.3 to 0.8ohm and low inductance (L=0.1 to 0.7mH) Energy = L * I * I so the higher inductance the better.

Do you have any recommendations for spark plug gap? Would you use a larger gap if using 300V output compared to the 150V? I’m guessing 0.025″ for TCI and 0.035″ to 0.045″ for your CDI.

Good question Keith.

IDK. Since it seems rational for CDI to take advantage of the boosted High Voltage to increase the gap. Unless it’ll be too large at start or idle…

For spark plug wires, do you recommend solid, copper core wire, 500 ohms per foot spiral wound resistance wire, or 50 ohms per foot spiral wound resistance wire for your ignition systems?

Although classical solid-core wire would simply work, but since voltage drop is no more a issue with DC-CDI and this ignition generates more EMI, I’d go with a carbon core.

Which resistance? IDK, probably the highest at 500ohm per 30cm

Thank you. MSD spiral wound wire is a popular choice in the USA. Their most popular wire is 500-ohm per foot.

I saw in one of your videos that you used a larger wire gauge for ground and Pin 1 to coil. Is 16 ga wire sufficient for all wiring or do you recommend 14 ga for ground & Pin 1 to coil?

Knowing that current peak can reach 4Amp, I’d use 14ga for + – and coil