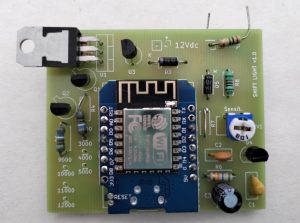

This unique device was created to assist a deaf motocross rider girl in feeling the engine, along with vibrations and throttle response.

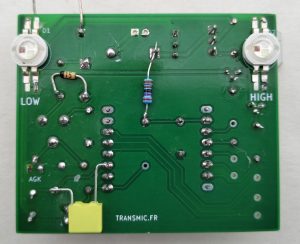

It turns on a green led if the engine revs are less than 3000rpm or a blue led if the revs are greater than 7000rpm.

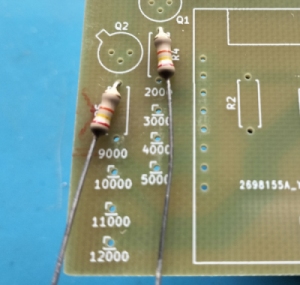

By moving two resistors through eight holes, those two trigger levels can be adjusted.

Features

- Low RPM trigger can be set to 2000, 3000, 4000 or 5000

- High RPM trigger can be set to 7000, 8000, 9000 or 10000

- Inductive sensor input (A simple wire wrapped around the sparkplug lead).

- Signal conditioning.

- Power Supply 7 to 15 Vdc

- Consumption : 0.3W to 3w

- Internal regulated power supply.

- Dimensions: 60 x 50 x 10 mm

- Weight: 20g

SPARK DETECTION.

Wrap 3 to 6 turns around the sparkplug wire and connect it to “Clamp” input on the PCB then adjust the sensitivity with RV1

If the signal is too weak, then add one wrap at a time until the signal is clear.

Signal strength is proportional to the number of wraps but too many will bring parasitic noise and give faulty readings.

If the signal is too strong, connect the wire to the “Clamp” input through the 1Mohm resistor to lower the signal and avoid parasitic noise going all over the place.

I experienced that a too strong signal makes both leds to flicker at all rpm, so I added a 1Mohm attenuator.

(You may wrap less turns around the sparkplug wire to lower the signal and perhaps use a shielded wire to hook to the pcb in order to avoid EMI.)

SETUP.

Solder the resistor’s leg into one of the 4 outputs.

PHOTOS.